The Importance of Alignment Checks

Alignment checking is an essential process across various industries, ensuring that your equipment and systems function at their best.

When misalignment occurs, you could face significant issues, ranging from decreased efficiency to costly repairs. This article delves into what alignment checks are, their purpose, and the potential consequences of neglecting them. You’ll discover the various methods available for effective assessments and when to conduct these checks.

A step-by-step guide on performing alignment checks will follow, along with a discussion on the benefits of maintaining regular alignment practices. By prioritizing alignment, you can enhance performance and extend the lifespan of your machinery.

Contents

- Key Takeaways:

- What is Alignment Checking?

- The Impact of Misalignment

- Types of Alignment Checks

- When to Conduct Alignment Checks

- How to Perform an Alignment Check

- Benefits of Regular Alignment Checks

- Frequently Asked Questions

- What are alignment checks and why are they important?

- How often should alignment checks be done?

- What are some signs that a machine or equipment needs an alignment check?

- Can alignment checks prevent breakdowns and downtime?

- Do alignment checks only apply to large machinery?

- Is it possible to perform alignment checks in-house?

Key Takeaways:

- Alignment checks are important for ensuring that all components and systems are working together properly for optimal performance and safety.

- Misalignment can lead to serious consequences such as increased wear and tear, decreased efficiency, and potential equipment failure.

- Regular alignment checks should be conducted according to recommended frequencies and indicators to prevent potential issues and maintain optimal performance.

What is Alignment Checking?

Alignment checking is a crucial element of vehicle maintenance that requires your attention. This process involves evaluating and adjusting the angles of your wheels to meet the manufacturer’s specifications.

It s not just about ensuring optimal tire wear; it’s also vital for your safety and overall vehicle performance. Misalignment can lead to handling difficulties and an increase in fuel consumption, which nobody wants.

Trust expert technicians equipped with cutting-edge tools to perform comprehensive alignment checks. Incorporating this into your regular maintenance routine will not only boost the lifespan of your tires but also significantly enhance your driving experience.

Definition and Purpose

The essence of alignment checking revolves around determining the precise angles of your vehicle’s wheels in relation to its body. This ensures optimal wheel alignment and enhances overall maintenance.

This crucial process boosts the lifespan of your tires and keeps your vehicle safe while enhancing vehicle performance. By regularly verifying your alignment, you can prevent uneven tire wear and improve fuel efficiency both essential for the long-term health of your vehicle.

Proper alignment preserves your vehicle’s handling characteristics, resulting in smoother steering and improved control on the road. Ultimately, the alignment checking process is a fundamental aspect of proactive vehicle maintenance, enabling your vehicle to operate at its full potential while safeguarding you and your passengers.

The Impact of Misalignment

Misalignment can profoundly affect your vehicle’s safety, causing a cascade of issues that jeopardize both performance and comfort.

When your wheels aren t perfectly aligned, you ll likely notice uneven tire wear, which not only shortens the lifespan of your tires but also hampers fuel efficiency.

Additionally, misalignment can result in handling problems, including steering difficulties, making it especially perilous during challenging driving conditions.

Taking the time to ensure proper alignment is key to maintaining your vehicle’s integrity and your peace of mind on the road.

Potential Consequences

The potential consequences of misalignment are significant and can include reduced vehicle safety, increased tire wear, and diminished fuel efficiency each of which can lead to costly repairs over time.

When your vehicle’s wheels are not properly aligned, it can create excessive strain on various components, leading to premature wear and tear.

Misalignment can throw your vehicle off course, posing a potential hazard to both drivers and pedestrians.

Alongside safety risks, misalignment often causes tires to wear unevenly, which not only shortens their lifespan but also negatively impacts handling and braking efficiency.

The additional drag from misaligned wheels can lead to higher fuel consumption, significantly increasing your operating costs over time.

Don’t wait for issues to arise regular inspections and timely adjustments are essential for maintaining your vehicle s performance and safety.

Types of Alignment Checks

Various types of alignment checks are used in auto repair, each tailored to address specific angles and adjustments crucial for maintaining your vehicle’s stability and performance. Methods like front-end alignment, four-wheel alignment, and thrust alignment use advanced tools to accurately measure and adjust the necessary angles.

By understanding these techniques, you can make informed decisions about your vehicle’s maintenance and alignment services, ensuring it runs safely and smoothly.

Methods and Techniques

Common alignment methods include front-end alignment, which fine-tunes the front wheels, and four-wheel alignment, which ensures all wheels are calibrated for optimal performance.

The introduction of laser alignment and computer-aided technology has transformed these processes, delivering precise measurements and faster adjustments. Technicians use beams with laser alignment to establish a reference line, ensuring that all wheels align accurately, enhancing safety and road handling.

Computer-based systems offer real-time diagnostics, quickly identifying misalignments and their causes. Each technique has its advantages: laser alignment is known for its accuracy, while computer systems streamline the diagnostic process, allowing for efficient service without long delays.

When to Conduct Alignment Checks

Conduct alignment checks regularly to ensure your vehicle’s safety and performance, especially after hitting a pothole or being in a collision. Routine checks are advised every 6,000 miles, but be alert for signs that indicate an immediate check is necessary.

Watch for uneven tire wear and steering difficulties. Recognizing these signs helps maintain your vehicle’s alignment and overall condition, ensuring a smoother and safer ride.

Frequency and Indicators

Don’t wait! Check your vehicle’s alignment every 6,000 miles as part of your regular maintenance routine. Look out for indicators like uneven tire wear or unusual steering responses, which may signal the need for more frequent checks.

Stay vigilant and attuned to your vehicle’s behavior to catch any potential alignment issues early. If your steering feels off-center or your vehicle pulls to one side, those are clear signs that an alignment check is due sooner than expected.

Listen for any strange noises while driving; they could indicate misalignment or uneven tire wear. Are you aware that acting quickly on these signs can keep you safer on the road and prolong your tires’ lifespan? Regularly addressing these factors can save you from costly repairs later on.

How to Perform an Alignment Check

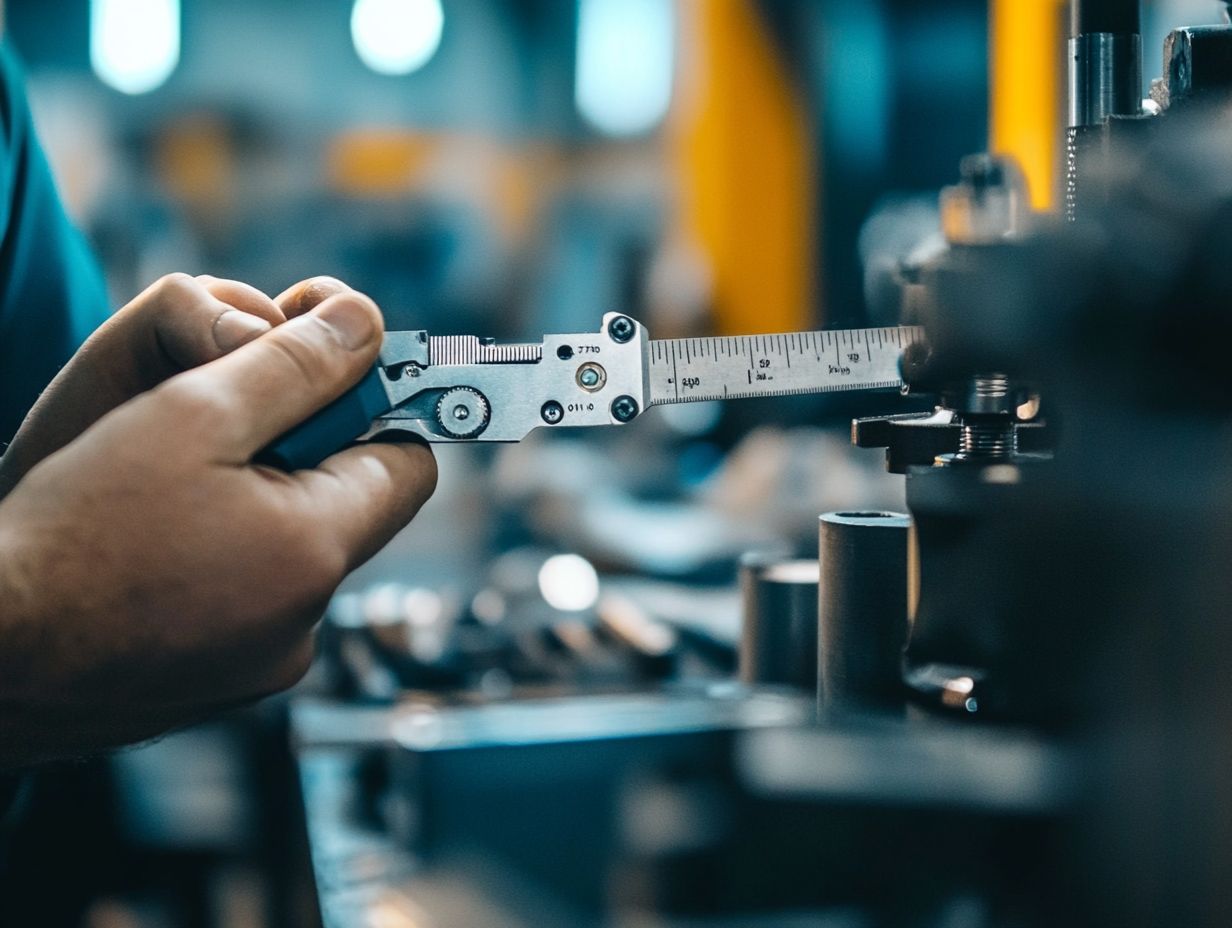

Conducting an alignment check involves a meticulous process that requires specialized machinery and the expertise of qualified technicians. Start with a thorough inspection of the vehicle’s components, focusing on the suspension system (the set of components that connect a vehicle to its wheels) and tires.

Next, technicians take precise measurements of the alignment angles. Any necessary adjustments restore proper alignment, ensuring your vehicle performs optimally and remains safe on the road.

Step-by-Step Process

The step-by-step process for conducting an alignment inspection begins with a visual check of your vehicle’s components. This is followed by measuring the wheel angles and making necessary adjustments.

This initial examination is crucial. It allows you to spot any visible wear or damage to the steering and suspension parts that could impact alignment. Next, precise measurements of the wheel angles camber (the tilt of the wheel), caster (the angle of steering), and toe (the direction the wheels point) are taken using specific tools to determine how well your wheels align with the manufacturer s specifications.

Correct adjustments enhance your vehicle’s handling. They also extend tire lifespan. Each of these steps is vital for ensuring that your vehicle operates smoothly and safely, underscoring the importance of maintaining proper wheel alignment.

Benefits of Regular Alignment Checks

Regular alignment checks yield numerous benefits that greatly improve vehicle care and overall performance. By ensuring that your vehicle is properly aligned, you can enjoy improved fuel efficiency, reduced tire wear, and a better driving experience all of which lead to significant cost savings over time.

Maintaining proper alignment extends the lifespan of your tires and suspension components. It also promotes the longevity and safety of your vehicle on the road.

Improving Efficiency and Preventing Damage

Conducting regular alignment checks is essential for enhancing vehicle efficiency and protecting vital components, such as tires and suspension systems. To learn more about the advantages, check out the benefits of regular alignment checks.

When your wheels are properly aligned, you can enjoy significant benefits, including improved fuel efficiency and a more comfortable driving experience. Misalignment can cause uneven tire wear, leading to premature replacements and potentially unsafe driving conditions. It also places unnecessary strain on the vehicle’s suspension, ultimately shortening its lifespan.

Regular checks are a must for keeping your vehicle in top shape! They safeguard not only performance but also the safety and longevity of your entire vehicle system.

Frequently Asked Questions

What are alignment checks and why are they important?

Alignment checks ensure that all components of a machine or equipment are in proper alignment. Misaligned equipment can lead to decreased efficiency, increased wear and tear, and potential safety hazards.

How often should alignment checks be done?

The frequency of alignment checks depends on the type of equipment and the level of use. As a general rule, alignment checks should be done at least once a year, or more frequently if the equipment is used heavily or experiences a lot of vibration.

What are some signs that a machine or equipment needs an alignment check?

Common signs of misalignment include unusual vibrations, excessive noise, uneven wear on components, and decreased efficiency. Address these issues immediately to avoid serious damage!

Can alignment checks prevent breakdowns and downtime?

Absolutely. By regularly performing alignment checks, you can identify and correct potential issues before they become major problems. This helps prevent breakdowns and minimizes downtime, saving both time and money in the long run.

Do alignment checks only apply to large machinery?

No, alignment checks are important for any type of machinery or equipment, regardless of size. This includes everything from small tools to large industrial machines. Proper alignment is crucial for the efficient and safe operation of all equipment.

Is it possible to perform alignment checks in-house?

Yes, with the right tools and training, alignment checks can be performed in-house. However, it is recommended to have a professional perform the checks, especially for complex or critical equipment, to ensure accuracy and proper adjustments.