What Are the Risks of Skipping Routine Maintenance?

Routine maintenance is often the unsung hero behind the longevity and optimal performance of your equipment. While you may recognize its importance, neglecting this crucial aspect can lead to costly consequences and operational inefficiencies.

This article delves into the significance of routine maintenance, shining a light on its benefits across various systems and equipment. It highlights often overlooked tasks and the risks of skipping maintenance. It also provides effective strategies to help you stay on top of your maintenance schedule.

Whether you re a homeowner or a business owner, grasping these elements can empower you to safeguard your investments and ensure smooth operations.

Contents

- Key Takeaways:

- Importance of Routine Maintenance

- Risks of Skipping Routine Maintenance

- Commonly Skipped Maintenance Tasks

- Tips for Staying on Top of Routine Maintenance

- Effective Strategies for Keeping Up with Maintenance

- Frequently Asked Questions

- What Are the Risks of Skipping Routine Maintenance?

- What Are the Risks of Not Regularly Cleaning and Inspecting Equipment?

- What Are the Consequences of Not Performing Routine Maintenance on a Vehicle?

- How Can Skipping Routine Maintenance Impact the Lifespan of Equipment?

- What Are the Potential Safety Hazards of Not Conducting Routine Maintenance?

- What Financial Risks Are Associated with Skipping Routine Maintenance?

Key Takeaways:

- Skipping routine maintenance can lead to costly consequences and potential risks for various systems and equipment.

- Regular maintenance helps prevent breakdowns, improves efficiency, and extends the lifespan of equipment, saving time and money in the long run.

- It is important to stay organized, create a maintenance schedule, and regularly check for commonly skipped tasks to ensure all systems and equipment are properly maintained.

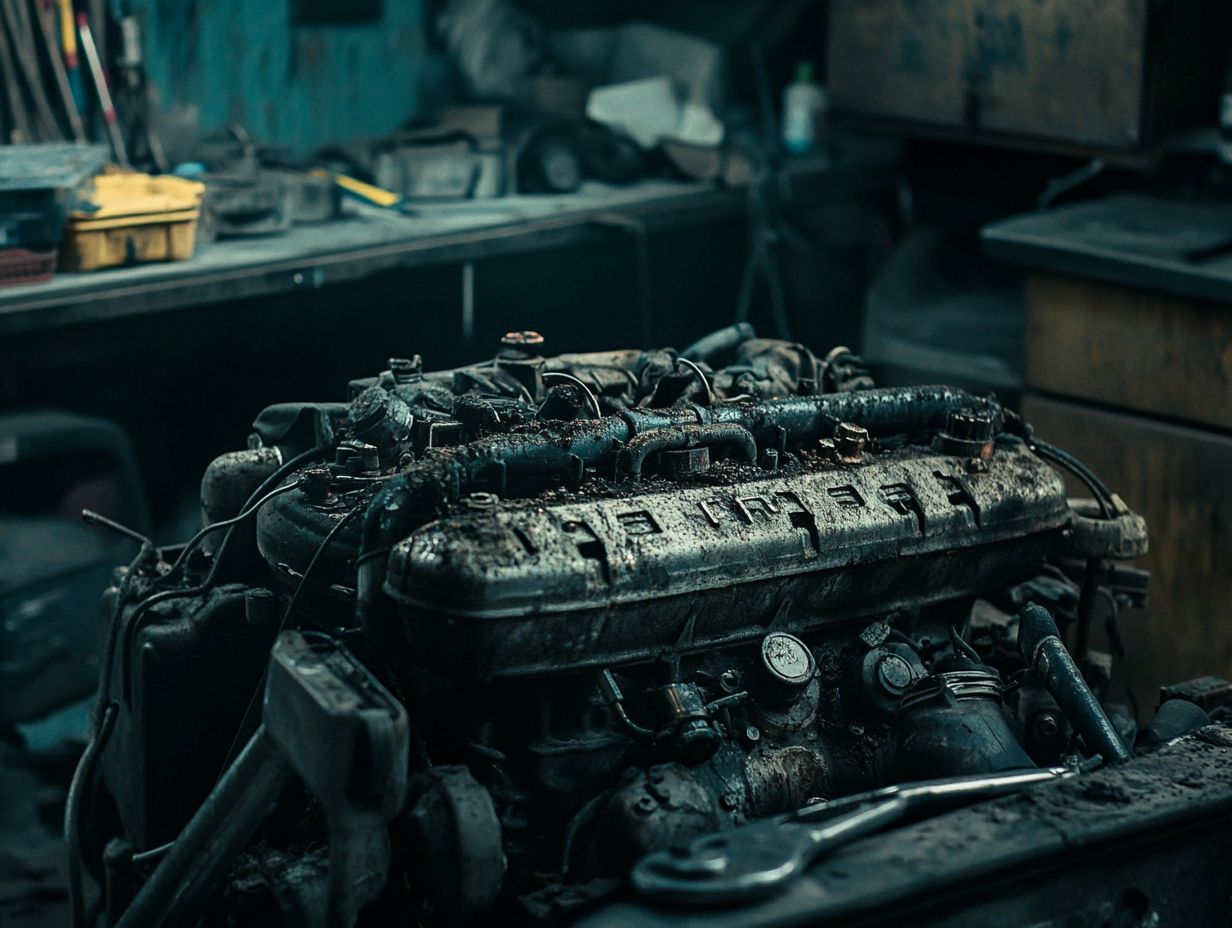

What is Routine Maintenance?

Routine maintenance refers to the regular actions you undertake to ensure the proper functioning and longevity of your fleet vehicles. This preventative maintenance is crucial for maintaining vehicle safety, reducing repair costs, and avoiding unscheduled downtime. By adhering to a well-defined maintenance schedule, you can optimize vehicle performance and minimize the risks associated with breakdowns.

Regular vehicle inspections and maintenance tasks significantly enhance the reliability of your fleet, promoting both driver safety and satisfaction.

The overarching goal of routine maintenance is to identify and address potential issues before they escalate into significant problems.

Key tasks involved in this process include:

- Regular oil changes to ensure the engine runs smoothly.

- Tire pressure checks, which are essential for optimal fuel efficiency and safety.

- Regular checks of important parts like brakes, lights, and batteries.

Emphasizing these activities can lead to improved fuel economy, extended vehicle lifespan, and enhanced operational efficiency. Proper maintenance schedules not only support compliance with regulations but also contribute to better fleet management overall, allowing you to maintain a competitive edge.

Importance of Routine Maintenance

Routine maintenance is vital for keeping your vehicle running smoothly and reliably. It builds your confidence on the road and enhances safety.

By routinely addressing maintenance issues, you significantly reduce the likelihood of breakdowns and the looming costs of repairs. Don’t wait until it’s too late! Keeping a detailed repair and maintenance history is essential for warranty claims and enhancing resale value, both of which can greatly benefit your fleet operations.

Benefits for Different Systems and Equipment

Routine maintenance offers a wealth of benefits across various systems and equipment within your fleet vehicles, ensuring they operate at their best and enjoy a longer lifespan. By prioritizing maintenance services, you can effectively tackle critical components like engine parts, brake systems, and tire performance, all of which enhance fuel economy.

Establishing a well-structured maintenance schedule is vital for nipping potential problems in the bud. Regularly checking engine oil levels and filters keeps things running smoothly, while timely brake inspections can prevent dangerous failures and boost safety.

Make maintenance a priority today! Don t overlook tire maintenance; proper rotation and alignment can significantly improve fuel efficiency and extend tire life. These practices not only make for a more pleasant driving experience but also help you sidestep unexpected repair costs. This ensures your fleet stays within budget while maximizing productivity.

As a result, the overall performance of your vehicles is significantly enhanced, making routine maintenance an essential strategy for any fleet operation.

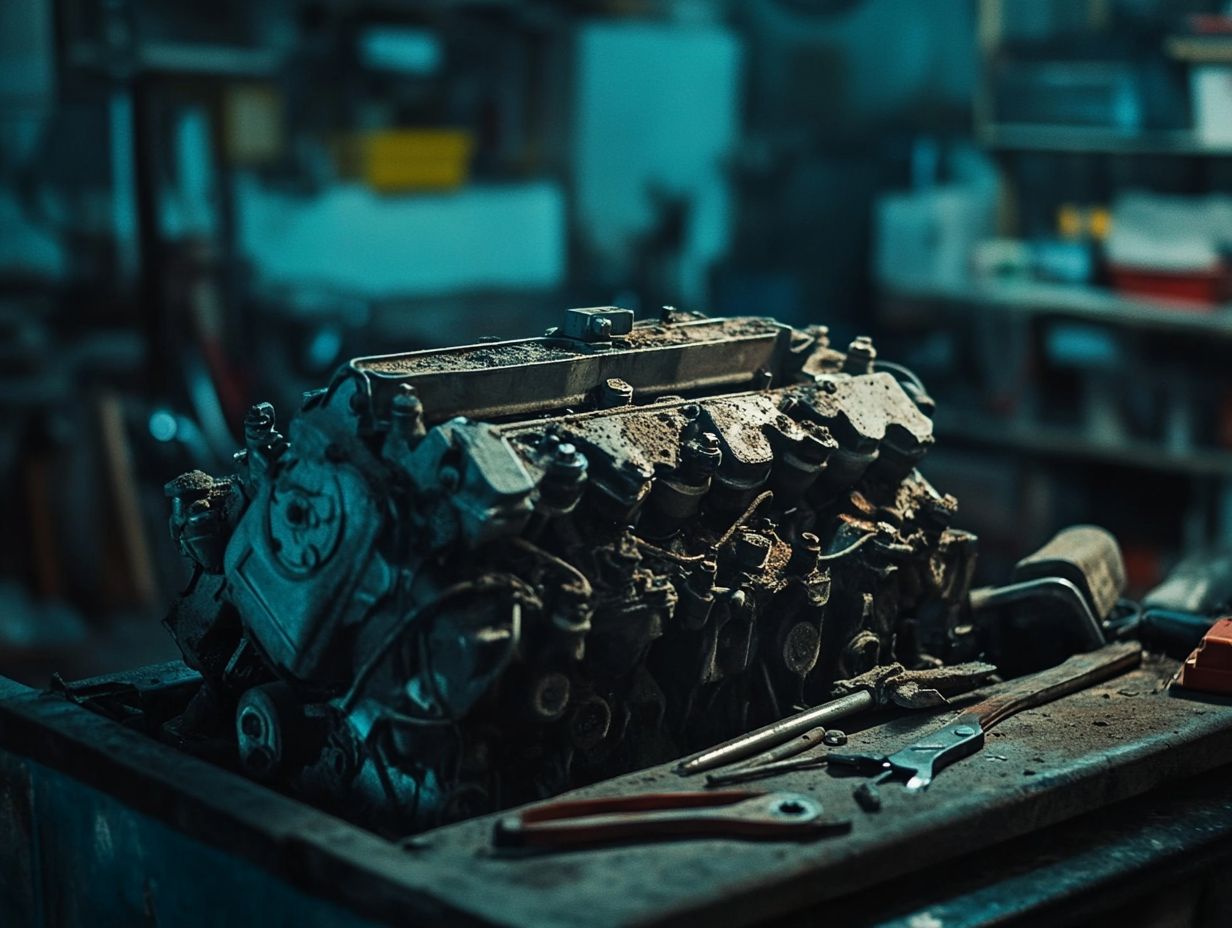

Risks of Skipping Routine Maintenance

The risks of overlooking routine maintenance are significant and multifaceted, presenting a host of safety concerns, high repair costs, and the potential for unexpected breakdowns.

Neglecting scheduled maintenance can lead to warranty issues, as missed claims can escalate repair costs over time. Your fleet vehicles may experience more mechanical failures, jeopardizing driver safety and adversely affecting the maintenance history.

Ultimately, this neglect can compromise the overall performance and reliability of your fleet, leading to greater challenges down the line.

Potential Consequences and Costs

Neglecting routine maintenance can lead to significant consequences, including soaring repair costs and unexpected breakdowns that can severely disrupt your fleet operations.

When maintenance is overlooked, you risk problems with the oil, worn tires, faulty safety devices, and other critical issues that inflate repair expenses. These financial strains not only hinder your fleet’s efficiency but also threaten to diminish the resale value of your vehicles.

Take, for example, the oversight of regularly checking brake fluid levels. Neglecting this task can put drivers at risk and potentially result in expensive accidents.

Similarly, ignoring tire pressure and tread wear can lead to blowouts on the road and reduced fuel efficiency, further driving up operational costs. Long-term neglect turns minor issues into major headaches, extending repair timelines and costs.

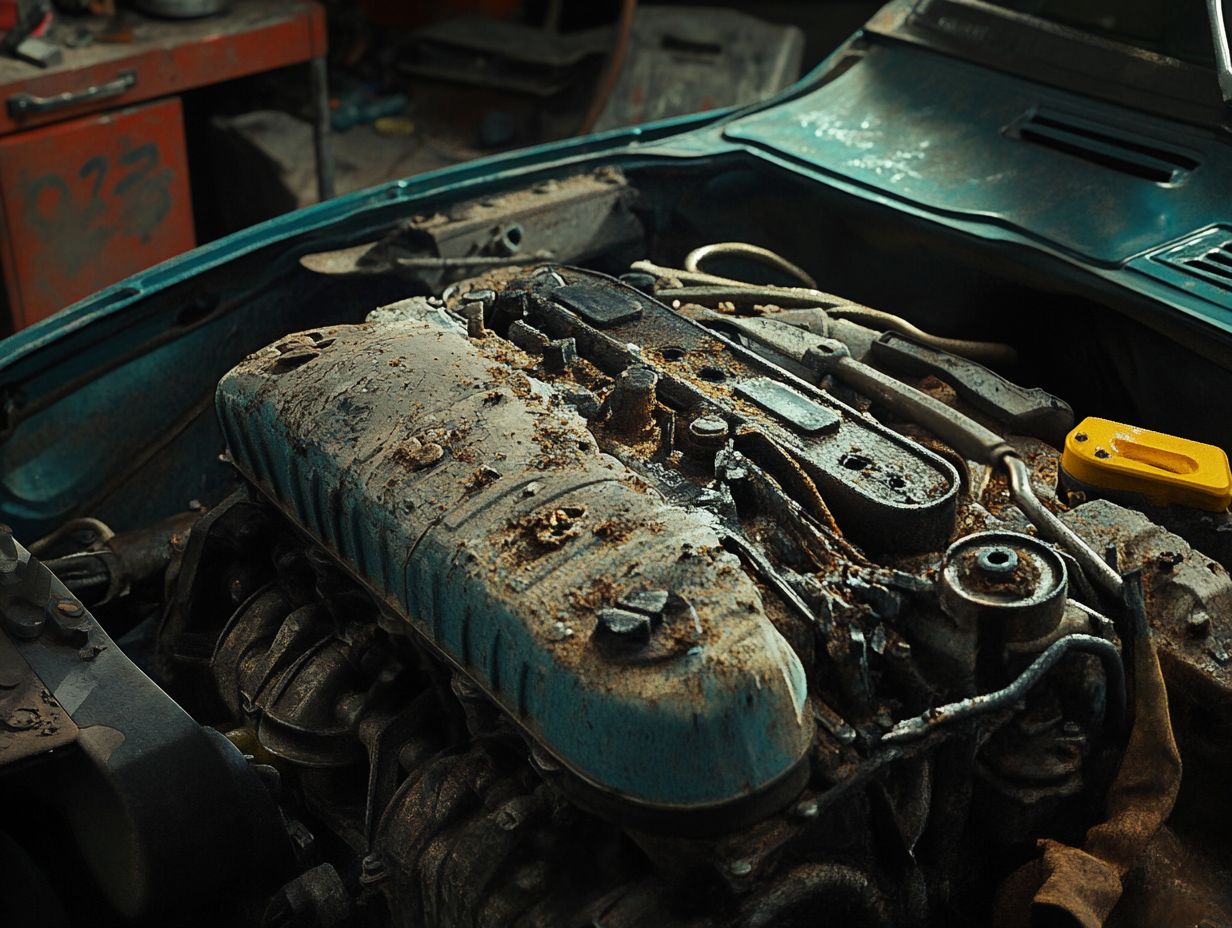

Commonly Skipped Maintenance Tasks

Overlooking routine maintenance tasks can lead to serious vehicle issues, putting both safety and reliability at risk.

Tasks like oil changes, tire pressure checks, and regular inspections are frequently ignored. However, they are essential for ensuring optimal performance and extending the life of your vehicle.

Neglecting these vital tasks can lead to skyrocketing repair costs and compromised safety due to malfunctioning safety features. Prioritizing maintenance tasks protects your investment and enhances your driving experience.

Areas Often Overlooked

Areas that are often overlooked during routine maintenance include worn tires, low fluid levels, and critical engine components like brakes and suspension systems.

Ignoring these essential areas not only puts your safety at risk but also opens the door to costly repairs and unexpected breakdowns.

Regularly checking tire pressure and tread depth is vital; under-inflated or excessively worn tires can lead to reduced traction and longer stopping distances.

It s equally important to monitor fluids such as oil, coolant, and brake fluid to prevent engine overheating and ensure optimal performance. Neglecting the brake system can create serious safety hazards.

By prioritizing these often-neglected aspects of vehicle maintenance, you can enhance both safety and longevity, ultimately fostering peace of mind while navigating the roads.

Tips for Staying on Top of Routine Maintenance

Staying on top of routine maintenance is crucial as a fleet manager. Implementing effective strategies, like establishing a well-structured maintenance schedule and diligently scheduling appointments, can make a significant difference.

By collaborating with ASE-certified mechanics professional automotive technicians recognized by the National Institute for Automotive Service Excellence and utilizing trustworthy inspection services, you can ensure that your vehicles receive the necessary automotive repair and maintenance tasks when needed.

This proactive approach will undoubtedly enhance both their performance and reliability. Start your maintenance checklist today and protect your fleet!

Effective Strategies for Keeping Up with Maintenance

Effective strategies for keeping up with maintenance include diligent record-keeping, strict adherence to maintenance tasks, and a steadfast commitment to preventive maintenance that minimizes risks. By meticulously maintaining service records and repair histories, you can effectively track maintenance frequency. This ensures your vehicles receive timely interventions and helps avoid costly repairs and unexpected breakdowns.

To elevate routine maintenance management, establishing a systematic scheduling approach can be immensely beneficial. By utilizing fleet management software software that helps manage vehicle maintenance you can automate reminders for upcoming services, significantly reducing the risk of missed deadlines. Categorizing your vehicles based on usage and age enables you to prioritize maintenance tasks according to urgency and complexity.

Engaging all team members in routine checks cultivates a culture of accountability and encourages proactive measures. Consistent training on maintenance protocols ensures that your employees understand the importance of these practices, ultimately leading to a highly efficient and well-maintained fleet that operates seamlessly.

Frequently Asked Questions

What Are the Risks of Skipping Routine Maintenance?

Skipping routine maintenance can lead to various risks and potential issues with your equipment or property. These risks include:

- Malfunctioning equipment

- Increased safety hazards

- Costly repairs

- Decreased operational efficiency

What Are the Risks of Not Regularly Cleaning and Inspecting Equipment?

Without regular cleaning and inspections, equipment can accumulate dirt and debris. This accumulation can cause malfunctions, decrease efficiency, and lead to safety hazards and potential breakdowns.

What Are the Consequences of Not Performing Routine Maintenance on a Vehicle?

Skipping routine maintenance on a vehicle can result in decreased performance, reduced fuel efficiency, and potential safety hazards. It can also lead to costly repairs and breakdowns.

How Can Skipping Routine Maintenance Impact the Lifespan of Equipment?

Skipping routine maintenance can significantly decrease the lifespan of equipment. Without proper maintenance, parts can wear out faster, leading to premature breakdowns and increased replacement costs.

What Are the Potential Safety Hazards of Not Conducting Routine Maintenance?

Skipping routine maintenance can lead to safety hazards, such as malfunctioning equipment, faulty electrical systems, and potential accidents. Regular maintenance is essential to keep your equipment running smoothly!

What Financial Risks Are Associated with Skipping Routine Maintenance?

Not performing routine maintenance can result in costly repairs and replacements. It can also lead to decreased efficiency and productivity, resulting in financial losses for businesses.